Aluminium Composite Material

Introduction

1. General description

HAOMEI industrial is primarily specializing in marketing and manufacturing aluminium composite panels. All purpose adhesive, super glue, silicone sealant, and aluminium plate, etc. can also be provided here.

2. Classification

As we have mentioned before, our aluminium composite panels fall into five primary categories, that is, internal wall panels, external wall panels, wooden grain panels, granite panels and fire resistance panels. There are totally hundred of types of aluminium plastic composite panels, with variety of colors for your option.

3. Raw materials and production techniques

Composed of superior quality antirust alloy sheets and high intensity polyethylene core sheets, and coated with world-class fluorocarbon resin, the aluminium composite panel quality is highly ensured. Additionally, our composite panels are made strictly in accordance with international standard ACP production standard.

Relying on our adoption of high quality raw material and advanced production techniques, all our aluminium composite panels feature strong weather resistance, uniform coating, smooth and even surface, and more.

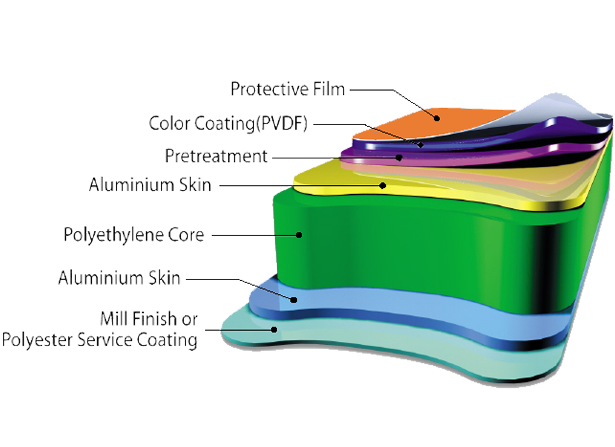

Structure

1. Protective film

2. PVDF clear coating

3. PVDF top coating

4. PVDF primer

5. Chromate treatment

6. aluminium skin

7. Chromate treatment

8. Bonding lamination layer

9. Nontoxic PE core material

10. Optional fire resistant and nontoxic PE core material

11. Optional back coating

Characteristics

1. Economy

Due to our adoption of high quality coatings, our aluminium composite panels are dispensed with frequent maintenance, thus saving a lot on maintenance cost. Hence, our composite panels are good decorative building material for high-rise buildings.

With regard to cities and regions with serious environment pollution, it is recommended to clean and maintain aluminium composite panels in a few years' time. Our panels are easy to be cleaned. They can be cleaned by neutral cleaning agent and clean water, and come out to be fairly new after cleaned.

2. Durability

Fluorocarbon coated aluminium composite panels are characterized by long service life, good weather resistance, high heat resistance and wear resistance, and good resistance to pollutions, and more.

3. Flatness

Our aluminium composite panels are manufactured with smooth and even surface, which can satisfy people's high demand on the appearance of modern constructions.

4. Light weight

By adopting light-weight aluminium alloy and superior quality plastics as primary raw material, aluminium composite panel is lighter than other types of decorative construction material. Hence, it is easy to install and needs shorter installation period.

5. Easy installation

Our aluminium composite panels are adaptable to various decoration requirements, because they are easy to be cut, grooved and bended.

6. Fireproofing

The exterior aluminium sheet of aluminium composite panels can effectively protect interior PE core material, because it can prevent heat conduction at the initial stage of combustion. The flame resistance of our aluminium plastic composite panels has reached international standard.

7. Design performance

aluminium composite panels can be made into different colors and styles, thus satisfying the diversified design requirements of architects.

8. Eco-friendliness

The surface coating is durable and has no changes, which produces no pollutants.

Technical property

| PHYSICAL PROPERTIES | |||||

|---|---|---|---|---|---|

| Item | Unit | Thckness | Standard | ||

| 3MM | 4MM | 6MM | |||

| Density | g/cm3 | 1.52 | 1.37 | 1.22 | ASTM D792 |

| Weight | kg/m2 | 4.55 | 5.48 | 7.34 | ASTM D792 |

| Thermal Expansion(20-600) | 10.6/oc | 22 | 24 | 25 | ASTM D696 |

| Thermal Conductivity(appearance) | w/m.k | - | 0.15-0.19 | - | ASTM C518 |

| Temperature for Thermal Deformation | oC | - | 113 | - | ASTM C648 |

| Acoustic Insulation(100-3200HZ) | dB | 24 | 26 | 27 | ASTM C413 |

| MECHANICAL PROPERTIES | |||||

| Item | Unit | Thckness | Standard | ||

| 3MM | 4MM | 6MM | |||

| Tensile Strength | Mpa | 45.8 | 48 | 38.2 | ASTM D638 |

| Yield Strength | Mpa | 43.4 | 44.2 | 30.4 | ASTM D638 |

| Extension Rate | % | 12 | 14 | 17 | ASTM D638 |

| Transverse Modulus | X10Mpa | 3.2 | 4.2 | 2.8 | ASTM D638 |

Applications

1. Wall and interior decoration of air ports, docks, stations, metros, hotels, restaurants, recreation places, top-grade residence, villas, office, and many other buildings.

2. Big billboards, shop windows, roadside news kiosks, bookstalls, telephone booths, traffic sentry boxes and filling stations.

3. Internal walls, ceilings, compartments, kitchens, toilets, etc.

4. Decoration for shops, cabinets, pillars, furniture, trains, automobiles, ships and carriages, etc.

5. Renovation and reconstruction of old buildings.

6. Cleaning and dust control projects.